Are you looking for a powerful tool to streamline your production processes and enhance efficiency in production management? Look no further than the Gantt chart. This versatile tool is widely used in project management to maximize resource allocation, improve project visibility, and optimize production planning. In this blog post, we will explore how you can use a Gantt chart to keep track of production and improve your overall production operations. From enhancing organization to monitoring production progress, Gantt charts offer a comprehensive solution for managing and tracking production activities. Let’s dive into the details of how Gantt charts can revolutionize your production management.

Streamlining Production Processes with Gantt Charts

The Power of Gantt Charts

Gantt charts are powerful tools for visualizing and managing production processes. By providing a clear timeline of tasks and their dependencies, Gantt charts enable teams to plan, schedule, and track progress with ease. This level of visibility and organization is essential for streamlining production processes and ensuring that projects stay on track.

Improving Efficiency and Productivity

One of the key benefits of using Gantt charts is the ability to identify bottlenecks and optimize resource allocation. By clearly mapping out the sequence of tasks and their durations, teams can identify areas where efficiency can be improved and make adjustments accordingly. This leads to increased productivity and a more streamlined production process overall.

Enhancing Communication and Collaboration

Gantt charts also play a crucial role in enhancing communication and collaboration within a team. By providing a visual representation of the production schedule, team members can easily see their individual responsibilities and how they fit into the larger project timeline. This level of clarity helps to minimize misunderstandings and ensures that everyone is on the same page, ultimately leading to smoother and more efficient production processes.

Enhancing Efficiency and Organization in Production Management

Implementing Lean Manufacturing Principles

One of the most effective ways to enhance efficiency and organization in production management is by implementing lean manufacturing principles. This approach focuses on eliminating waste, streamlining processes, and continuously improving operations. By identifying and eliminating non-value-added activities, companies can optimize their production processes and improve overall efficiency.

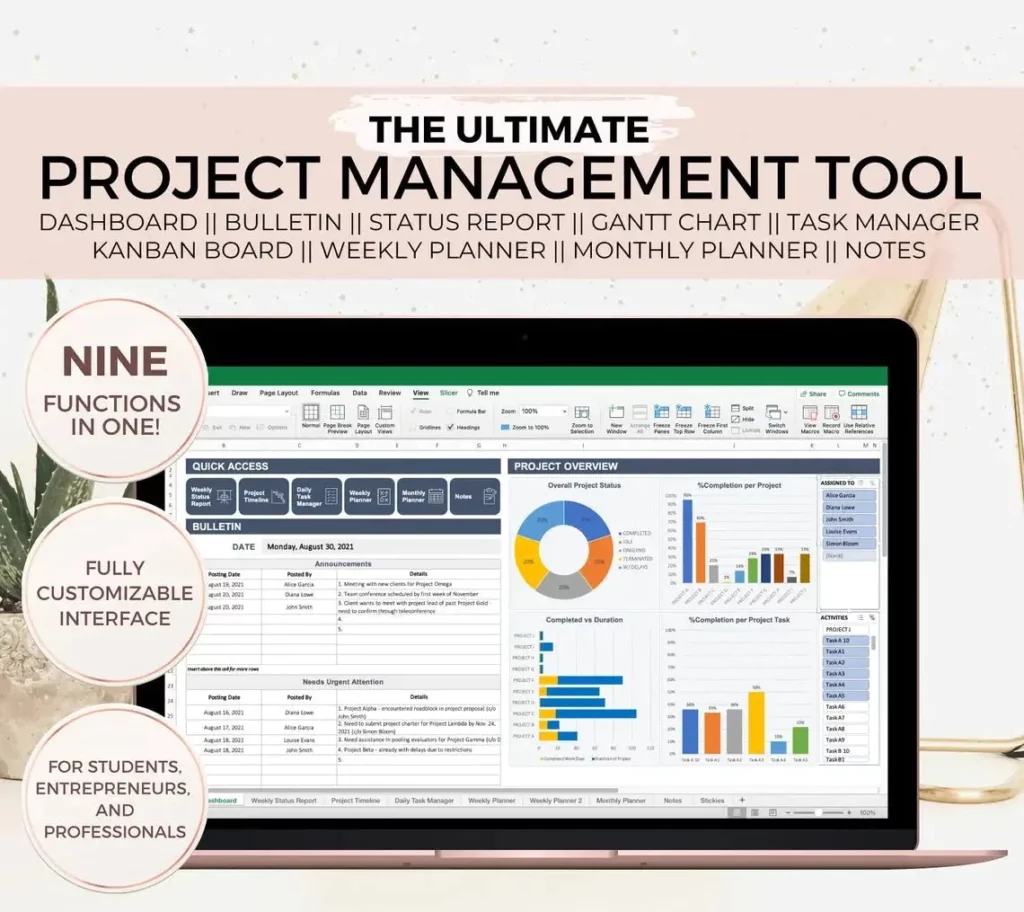

Utilizing Advanced Production Planning and Scheduling Software

Another key strategy for enhancing efficiency and organization in production management is by utilizing advanced production planning and scheduling software. These tools can help companies optimize their production schedules, minimize downtime, and improve resource utilization. By leveraging real-time data and advanced algorithms, production managers can make more informed decisions and ensure that production processes are running at peak efficiency.

Implementing Total Quality Management (TQM) Practices

Implementing Total Quality Management (TQM) practices is essential for enhancing efficiency and organization in production management. TQM focuses on continuous improvement, customer satisfaction, and the involvement of all employees in the quality improvement process. By implementing TQM practices, companies can improve product quality, reduce defects, and enhance overall efficiency in production processes.

Maximizing Resource Allocation and Scheduling with Gantt Charts

Efficient Resource Allocation

One of the key benefits of using Gantt charts is the ability to efficiently allocate resources. By visually representing the tasks and their timelines, project managers can easily identify where resources are needed and when, allowing for better planning and utilization of resources. This can lead to cost savings and improved productivity, as resources are allocated in a way that maximizes their impact on the project.

Optimized Scheduling

Gantt charts also play a crucial role in optimizing project scheduling. With a clear timeline of tasks and their dependencies, project managers can identify potential bottlenecks and adjust the schedule accordingly. This ensures that tasks are completed in the most efficient order, minimizing delays and maximizing the overall project timeline. By having a visual representation of the project schedule, teams can stay on track and meet deadlines more effectively.

Improved Communication and Collaboration

Another advantage of using Gantt charts is the improved communication and collaboration among team members. With a shared visual representation of the project timeline, everyone involved can easily see the progress of tasks and understand their role in the overall project. This fosters better teamwork and coordination, leading to smoother project execution and better outcomes.

| Task | Start Date | End Date |

| Task 1 | 01/01/2023 | 01/15/2023 |

| Task 2 | 01/16/2023 | 01/31/2023 |

| Task 3 | 02/01/2023 | 02/15/2023 |

- Visual representation of tasks and timelines

- Identification of resource needs

- Adjustment of project schedule

- Improved communication and collaboration

Improving Project Visibility and Tracking in Production Operations

The Importance of Project Visibility

Project visibility is crucial in production operations as it allows teams to have a clear understanding of the status of each project. With improved visibility, teams can identify potential bottlenecks, track progress, and make informed decisions to ensure projects are completed on time and within budget. Lack of visibility can lead to delays, cost overruns, and inefficiencies, making it essential for organizations to prioritize project visibility in their production operations.

Challenges in Tracking Projects in Production Operations

Tracking projects in production operations can be challenging due to the complexity of the processes involved. Multiple tasks, resources, and dependencies need to be managed simultaneously, making it difficult to keep track of everything. Additionally, manual tracking methods are prone to errors and can be time-consuming, leading to inaccuracies and delays. Organizations need to address these challenges to improve project tracking and ensure smooth operations.

Implementing Solutions for Improved Visibility and Tracking

There are several solutions that organizations can implement to improve project visibility and tracking in production operations. Utilizing project management software with real-time dashboards and reporting capabilities can provide teams with a centralized platform to monitor project progress, identify issues, and collaborate effectively. Automation tools can also streamline tracking processes, reducing manual errors and improving accuracy. By integrating these solutions into their operations, organizations can enhance project visibility and tracking, leading to improved efficiency and productivity.

Optimizing Production Planning and Monitoring with Gantt Charts

The Importance of Gantt Charts in Production Planning

Gantt charts are an essential tool for production planning and monitoring. They provide a visual representation of the project schedule, allowing for better coordination and allocation of resources. By using Gantt charts, production managers can easily identify bottlenecks, track progress, and make informed decisions to optimize production processes.

Benefits of Using Gantt Charts in Production Monitoring

One of the key benefits of using Gantt charts in production monitoring is the ability to clearly see the dependencies between tasks. This allows for better coordination and sequencing of activities, leading to improved efficiency and reduced lead times. Additionally, Gantt charts enable production managers to easily identify and address potential delays, ensuring that production stays on track.

Another advantage of using Gantt charts is the ability to communicate the production schedule effectively to all stakeholders. This helps to align expectations and ensure that everyone is on the same page, leading to smoother production processes and better overall outcomes.

Implementing Gantt Charts in Production Planning

When implementing Gantt charts in production planning, it’s important to ensure that all relevant tasks and milestones are included. This may involve breaking down larger production processes into smaller, more manageable tasks, and identifying the dependencies between them. Additionally, it’s important to regularly update the Gantt chart to reflect any changes or new developments in the production process.

Furthermore, it’s crucial to involve all relevant stakeholders in the creation and maintenance of the Gantt chart. This ensures that everyone is aware of the production schedule and can contribute their insights and expertise to optimize the planning and monitoring process.

Conclusion

In conclusion, Gantt charts are an invaluable tool for streamlining production processes and enhancing efficiency and organization in production management. By maximizing resource allocation and scheduling, Gantt charts enable businesses to optimize production planning and monitoring, ultimately improving project visibility and tracking in production operations.

With the ability to visualize timelines, dependencies, and progress, Gantt charts provide a comprehensive overview of production activities, allowing for better decision-making and proactive problem-solving. By incorporating Gantt charts into production management, businesses can effectively manage resources, meet deadlines, and deliver high-quality products to customers.

As you consider how to use a Gantt chart to keep track of production, it’s important to remember that the key to success lies in leveraging this powerful tool to its full potential. By embracing Gantt charts as a central component of production planning and monitoring, businesses can achieve greater operational efficiency and drive continuous improvement in their production processes.

Take the first step towards optimizing your production management with Gantt charts and unlock the full potential of your business’s production capabilities.